Did you know the AI Robots Market was worth USD 15.2 billion in 2023? It’s expected to jump to USD 111.9 billion by 2033. This huge growth, with a CAGR of 22.1%, shows how robotics in factories are on the rise. Industries are moving to manufacturing robots for better efficiency, productivity, and safety.

Today, industrial automation is not just a trend; it’s a must for staying ahead. Robotics are changing how we make things, making them faster and more precise. I’ll explore the latest robotics advancements and why they’re key for future manufacturing success.

Key Takeaways

- The AI Robots Market is projected to grow significantly from USD 15.2 billion to USD 111.9 billion by 2033.

- Manufacturing robots currently dominate the industrial robot market, comprising 60% of all robot types.

- Industrial automation is essential for competitiveness in the modern manufacturing sector.

- Robotics are revolutionizing traditional methods, increasing both accuracy and speed in production.

- Understanding new technologies in this field is critical for future business success.

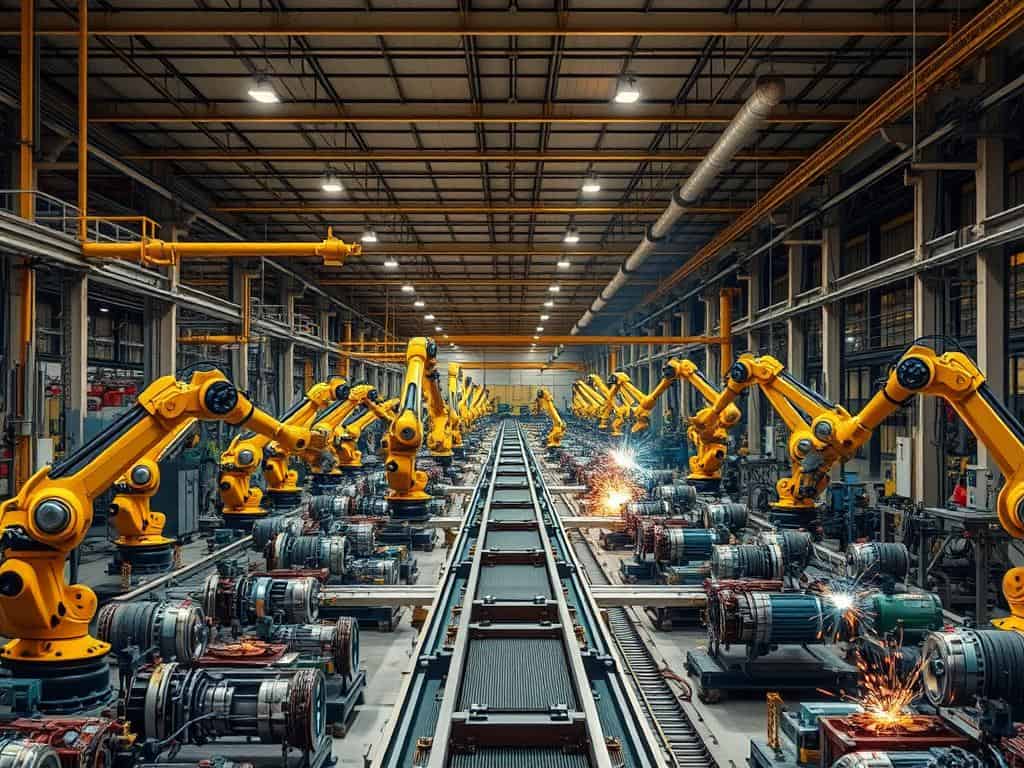

The Rise of Robotics in Factories

The way we make things has changed a lot with the rise of robotics and automation. Today, 4,281,585 industrial robots are working all over the world, up by 10% from last year. These robots help make things faster and better by doing tasks on their own.

Defining Industrial Automation and Robotics

Industrial automation means using control systems to run factory equipment. It combines with robotics to make production smoother. In 2023, over 541,302 new robots were added, showing how fast this technology is growing.

The Fourth Industrial Revolution

Klaus Schwab calls our time the Fourth Industrial Revolution. It’s all about new tech like advanced robotics and AI changing how we work. This makes businesses more flexible and able to meet demand quickly. Most of these new robots went to Asia, making up 70% of all installations.

Innovative Humanoid Robots in Manufacturing

The world of manufacturing is changing fast, thanks to humanoid robots. These robots are making production better and opening new possibilities in different industries. Companies are working on humanoid robots that can do many things and solve problems in modern factories.

Spotlight on Key Players

Companies like 1X Technologies, Agility Robotics, Apptronik, and Tesla are leading in humanoid robotics. Apptronik got $350 million to make more of its Apollo robots. Apollo can carry 55 pounds and uses batteries that last four hours.

Tesla’s Optimus project wants to make tasks in Gigafactories easier. This shows big companies are serious about using humanoid robots.

Specific Use Cases and Applications

Humanoid robots are making manufacturing better and safer. For example, Digit from Agility Robotics is great for last-mile delivery and warehouse work. It has human-like skills.

BMW’s Spartanburg plant uses robots for precise work. KIME can serve 253 items per hour, showing robots’ flexibility in many roles.

Innovative humanoid robots are changing how we do tasks and are setting a new standard in manufacturing. As more companies get interested, these robots will keep changing industries. They make work more efficient and safe in many areas.

The Role of Smart Factories in Modern Manufacturing

Smart factories are key to the future of making things. They use new tech like automation, AI, and IoT to change old ways of working. This makes making things better and more connected.

This change helps solve big problems like not enough workers and needing to make things just for one person. It makes work more efficient and helps meet new demands.

The Future of Production

The smart manufacturing tech market is expected to grow a lot. It’s going from US$254.24 billion in 2022 to US$787.54 billion by 2030. Companies see how important smart factories are.

A 2022 MHI Annual Industry Report shows 54% of companies have trouble finding and keeping good workers. This digital talent gap makes it urgent for factories to use new tech. It helps make work easier and helps train workers.

For example, Sunview Patio Doors saw a big return on their smart factory investment in just 16 months. It made making things more flexible and custom, cutting down on downtime. AMRs make work safer and more efficient by moving around easily.

This level of progress lets companies meet market needs quickly. In fact, 97% of manufacturers plan to use smart manufacturing tech in the next two years.

As making things gets more complex and urgent, the need for automation grows. The 2022 MHI report says fast response times are a big worry. Smart factories help make things faster and cheaper.

As we move into a more digital world, smart factories will change how we make things. They will help make the industry more sustainable and skilled.

Conclusion

Looking back, the impact of robotics on manufacturing is huge. It started with Unimate in 1961 and grew with collaborative robots in the 2000s. Robotics has changed how we make things, making production better, more precise, and safer.

But, there are challenges ahead. Automation might replace some jobs, but it also means new skills for others. It’s important to adapt and learn to keep up with these changes.

In the end, robotics has a big future in making things. With AI and machine learning, and a smart approach to work, we’re set for a better future. I’m hopeful that we’ll see all the good that automation can do, leading to growth and innovation in making things and more.